In the Australian construction industry, implementing effective risk management practices is essential. One crucial tool is the Safe Work Method Statement (SWMS).

In this comprehensive guide, we will delve into SWMS meaning. In addition, we will look at its purpose, which trades need it, who completes it, when it should be completed, and how it differs from a Job Safety Analysis (JSA).

So, if you need to know SWMS meaning, we've outlined it for you.

Understanding SWMS meaning, its purpose, and its role in risk management is crucial for builders and tradespeople

SWMS Meaning

A Safe Work Method Statement (SWMS) is a comprehensive safety document used in the construction industry in Australia. It outlines high-risk construction work (HRCW) performed on site, the associated hazards, and the control measures to mitigate risks. Importantly, it serves as a guide to conduct work safely, and ensure everyone involved is aware of potential dangers. In addition, it ensures workers are equipped with the necessary information to execute the task securely.

For more, visit “what is a SWMS”.

Purpose of a SWMS

The primary purpose of a SWMS is to systematically identify, assess, and control risks associated with high-risk construction work.

Moreover, it provides a detailed plan for managing hazards, that helps create a safer work environment.

Which Trades Require a SWMS?

A SWMS is an essential tool for builders and trades involved in high-risk construction activities. This includes, but is not limited to:

- Construction workers

- Carpenters

- Roofers

- Electricians

- Plumbers

- Welders

- Scaffolders

- Demolition crews, and

- Crane operators

Understanding the specific risks associated with each trade is crucial to develop an effective SWMS.

To find a SWMS template for your trade, search the Builder Assist SWMS documents.

Or, for a better understanding of safety and quality assurance documents required for your trade, visit Tradespeople.

Who Completes the SWMS?

The responsibility to create a SWMS ultimately lies with the person conducting the business or undertaking (PCBU). However, it is often filled out by the principal contractor or the subcontractor performing the high-risk work. Collaboration between different parties ensures that the SWMS accurately reflects the conditions on-site and incorporates input from those with direct knowledge of the tasks involved.

When Must a SWMS Be Completed?

A SWMS must be completed before the commencement of any high-risk construction work.

It is a proactive measure designed to ensure risks are identified and mitigated before work begins. This promotes a safe work environment throughout the project's lifecycle.

The Hierarchy of Controls and SWMSs

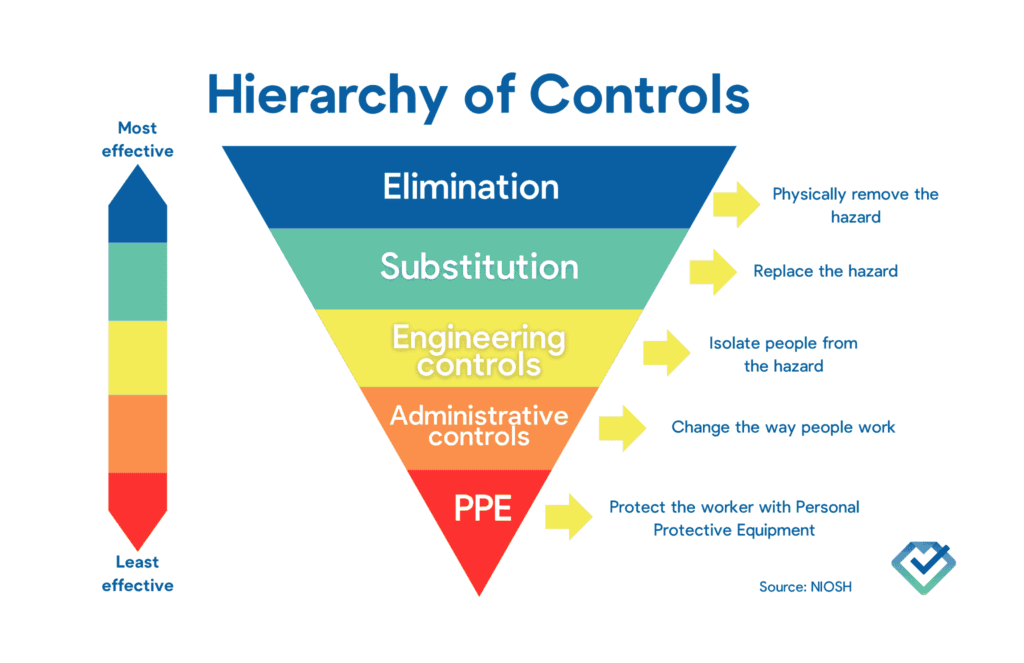

The Hierarchy of Controls is a well-established framework in work health and safety that outlines various strategies for managing and controlling workplace hazards.

The hierarchy is typically presented as a pyramid, with the most effective controls at the top and the least effective at the bottom.

The Controls, in order of effectiveness, are elimination, substitution, engineering controls, administrative controls, and personal protective equipment (PPE).

In the context of Safe Work Method Statements (SWMS), the Hierarchy of Controls plays guide the development and implementation of risk control measures.

A well-structured SWMS should reflect the principles of the Hierarchy of Controls. Subsequently ensuring risks associated with high-risk construction work are effectively managed.

For example:

Elimination

A SWMS should aim to eliminate high-risk activities wherever possible. Assess if the task can be removed entirely.

Substitution

A SWMS should aim to substitute high-risk activities wherever possible. Assess if the task can be replaced with a safer alternative.

Engineering Controls

A SWMS should outline engineering controls that are designed to isolate workers from the hazard. This may involve the use of machinery, barriers, or other physical modifications to reduce the risk.

Administrative Controls

The SWMS should include administrative controls as part of the risk management plan. This might involve establishing safe work procedures, scheduling work to minimise exposure, or implementing training programs to enhance worker awareness.

Personal Protective Equipment (PPE)

While PPE is the least effective control measure according to the Hierarchy, SWMSs should still address its use. Identify the type of PPE required for the task and ensure workers are trained in its correct use.

A SWMS aligns with the Hierarchy of Controls by systematically addressing and implementing control measures in a prioritised manner. By incorporating these principles, the SWMS becomes a comprehensive tool that not only identifies and assesses risks, but also provides a clear plan for controlling risks in a way that aligns with the Hierarchy of Controls. This integrated approach contributes to a safer work environment and ensures compliance with health and safety regulations in the Australian construction industry.

For more information on the Hierarchy of Controls visit “The Hierarchy of Control in WHS”.

SWMS vs JSA

The difference between a JSA and SWMS:

- a JSA is a method which outlines the hazards associated with a particular job or task.

- a SWMS is a method which outlines the hazards associated with a particular job or task, however a SWMS is specific to the construction industry and is required for all high-risk construction work

While the job steps, hazard identification and control measures for specific tasks are alike, SWMSs are prescribed for all high-risk construction work (HRCW) under safety regulations in Australian States. In addition, compliance with the SWMS is mandated, so if the workers are not complying 100% with the SWMS, work must stop and the SWMS must be reviewed.

For more, visit “What is the difference between a JSA and a SWMS?”

In the Australian construction industry, understanding SWMS meaning, its purpose, and its distinct role in risk management is crucial for builders and tradespeople. By implementing effective SWMSs, the industry can continue to prioritise safety and protect workers.